Case Study

Transforming MedTech Operations and Device Quality through Design History File Compliance

Products Supported

Sites Exhibit Standardization

Documents Legalised

Background

With a global presence in over 25 countries and sales in over 100 countries, our client is a medical technology leader with a comprehensive portfolio designed to maximise mobility and improve health.

To address audit findings, our client initiated a CAPA (Corrective Action and Preventive Action) program and a Design History File (DHF) project. The objectives for this were threefold: to ensure the remediated DHFs effectively reduce patient safety risks, to align all documentation and data with Design Control and Risk Management System standards, and to achieve consistent DHF data output in full compliance with 21CFR 820.30, ISO 13485:2016 Section 7.3, and ISO 14971:2019.

Challenge

Tight deadlines and a lack of input documents created pressing challenges for the client in updating Design History Files and managing the high volume of work involved.

With stringent oversight by regulatory authorities for medtech OEMs, Importers and Distributors, it was crucial for the client to maintain a comprehensive Quality Management System (QMS) and demonstrate unwavering adherence to regulatory compliance. A primary hurdle for the client was to adhere to the latest regulatory standards by revisiting established processes and re-testing devices for state-of-the-art compliance.

Solution

Tata Elxsi collaborated with the client to establish a Center of Excellence (CoE) that acted as an extended arm of the customer’s internal Design History File (DHF) team. The CoE model enabled the building of integrated teams and streamlined operations, thereby, creating synergies among various product documentation activities across departments and stakeholders.

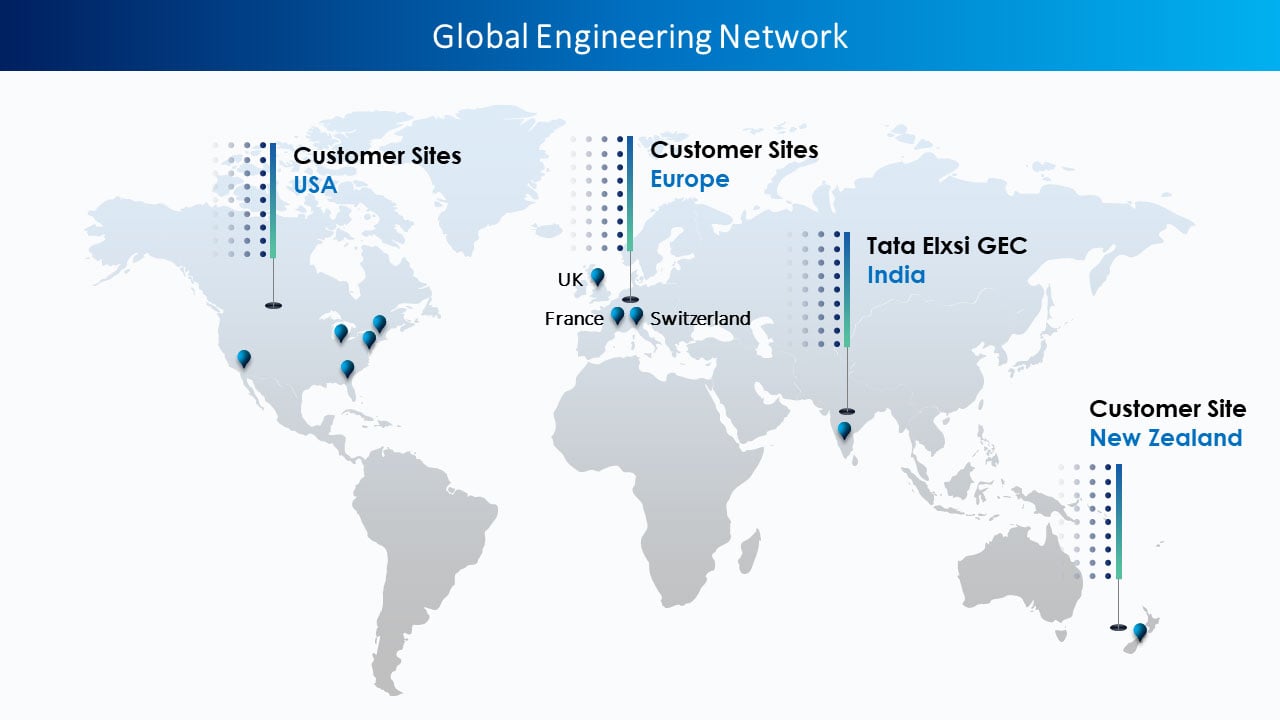

We supported the client across multiple product lines, including surgical instruments and implants. Tata Elxsi successfully delivered global Design History File (DHF) support coverage, ensuring standardisation across multiple regions.

Impact

The collaborative endeavor significantly transformed the client's operations.

By streamlining processes and optimizing workflows, we attained a remarkable 100% on-time compliance with all deadlines. Moreover, By leveraging automation, we achieved a 30% improvement in time-to-market for multiple products.

This streamlined approach led to significant cost reductions, achieving a notable 25% cost saving across Design History File (DHF) operations.

The creation of over 100 training artifacts solidified the positive impact of the Knowledge Enhancement Initiative on the client's internal capabilities and compliance efforts.

Services rendered

Tata Elxsi

- Strategy and Planning

- Gap Assessment and Consulting

- Remediation and Implementation

- Design History File creation during NPD

- Risk Management

- QMS Update and Audit Support

- Non- conformity assessment and resolution