Background

In the realm of EV technology, Lithium-ion batteries (LiB) have emerged as a prominent choice due to their high energy density and low self-discharge properties.

Harnessing their potential requires meticulous safety measures, as they can pose a risk of fire if not managed with precision.

Recognizing this critical need, Tata Elxsi engaged in a strategic collaboration with Renesas Electronics within the Next Generation EV Innovation Center (NEVIC). This partnership enables a cutting-edge Battery Management System (BMS) that guarantees the safe operation of LiBs by consistently adhering to their Safe Operating Area (SOA).

Challenge

Developing a Battery Management System (BMS) for the global EV market poses multifaceted challenges. The surging demand for electric vehicles necessitates the rapid integration of an efficient and reliable BMS, while the absence of India-specific R&D solutions complicates the process.

Customizing the BMS to align with specific local weather conditions presents a formidable challenge along with estimating parameters due to Li-Ion cell instability and inherent characteristics. Mitigating electrical short circuits and thermal runaway risks adds to this complexity.

Delivering a reliable and safety-compliant BMS remains vital for enhancing overall battery pack performance and safety.

Solution

Tata Elxsi helped develop a comprehensive and robust intelligent BMS platform which is a comprehensive and robust platform that ensures active monitoring of measurable parameters such as voltage (V), current (I), and temperature (T). It also helps estimate non-measurable parameters like State of Charge (SOC) and State of Health (SOH).

This holistic approach extends battery life, optimizes battery service, and predicts power states within defined constraints.

The solution provides essential safety features including overcharge, over-discharge, over-temperature, and overcurrent protection, along with effective fault management and cell balancing options.

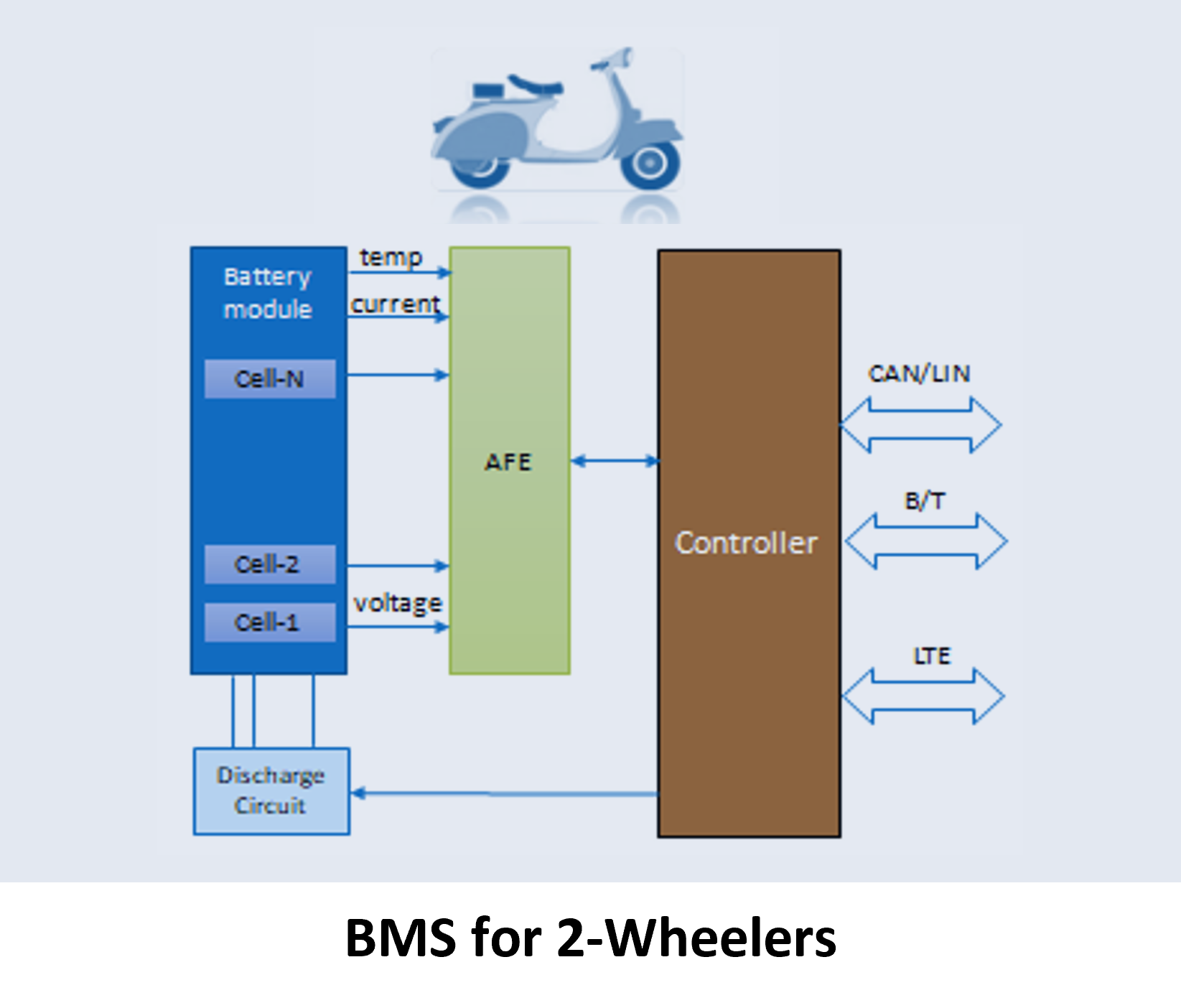

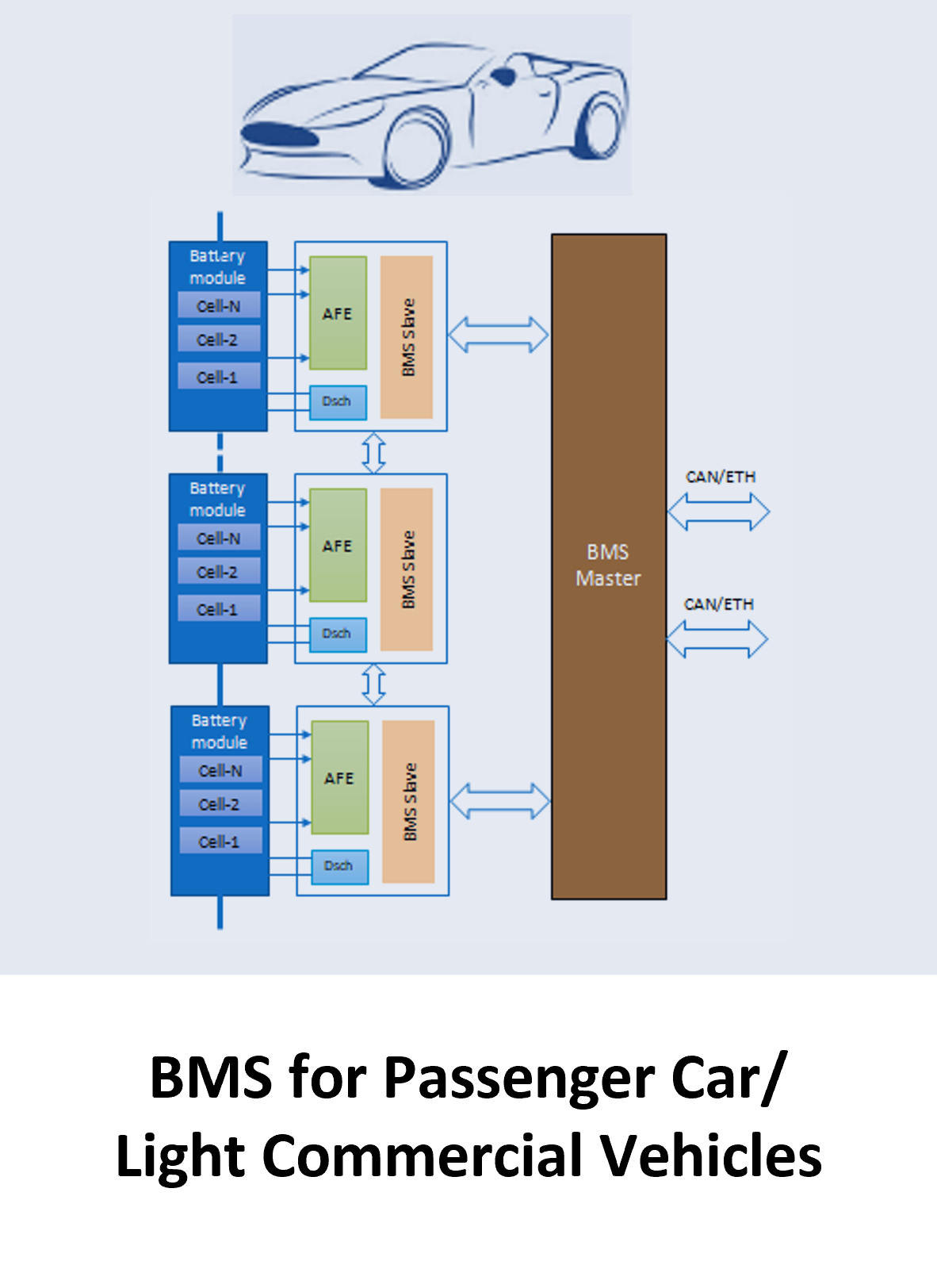

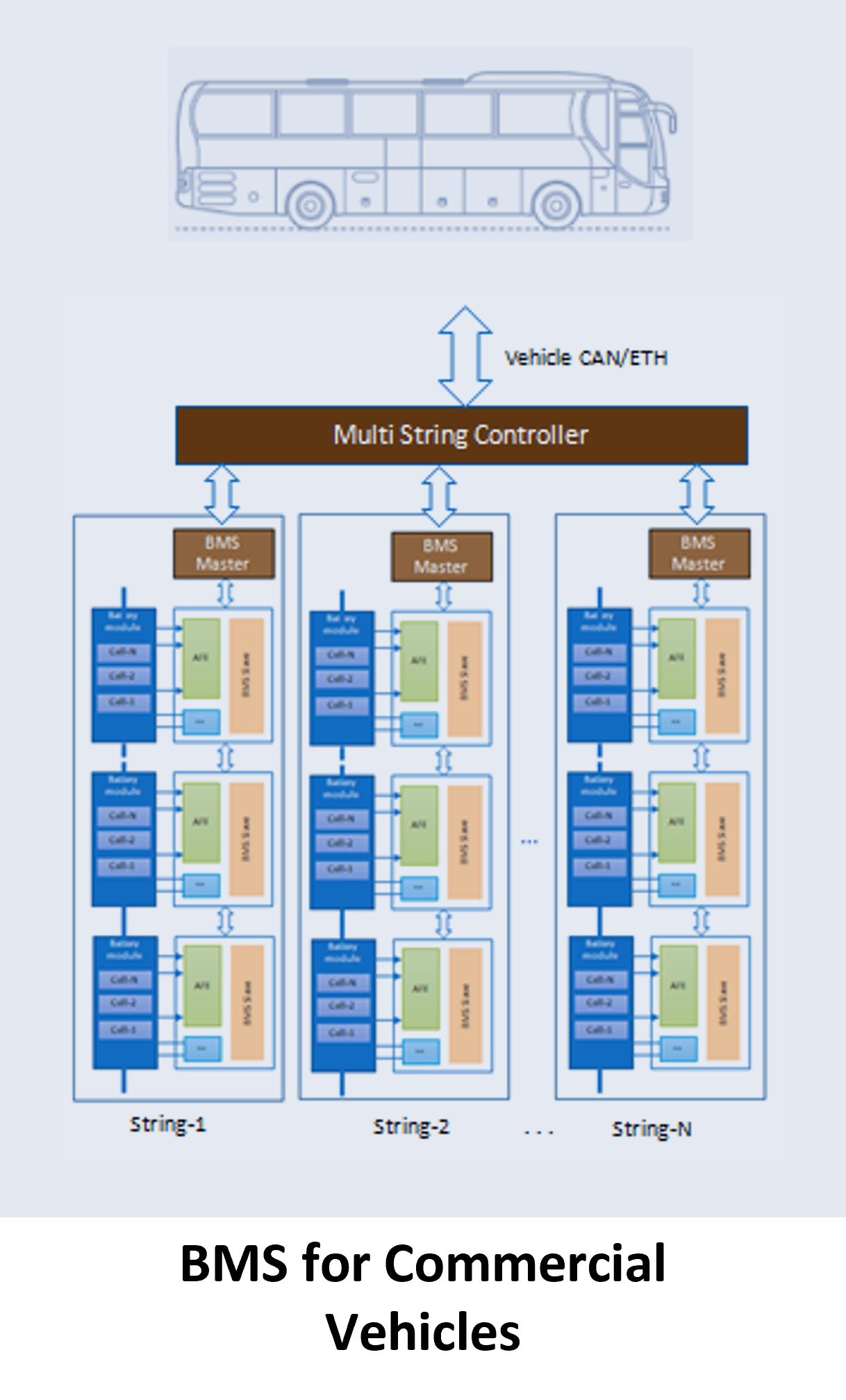

Its modular and scalable architecture ensures adaptability across various EV applications.

Impact

The BMS developed by Tata Elxsi in collaboration with Renesas provides:

- Scalable BMS architecture

- Reusable HW/SW modules for easy customization

- Application software based on MATLAB/Simulink Models

- Optimized development cost and faster time to market

- Provides multiple Battery chemistries support

- Improved Fault tolerant System and better Fault reaction time

- GUI that sets the battery configurations, faults threshold limit, and other configurable parameters as needed for different application requirements.

- Supports Over-The-Air (OTA) Update and secure boot

- Controller is capable to meet functional safety and cyber security requirements.

- A one-stop solution for Hardware, software, testing, validation, and digital platform for BMS applications.

"Renesas is pleased to work with Tata Elxsi, a proven leader in design and technology services for the automotive industry. This collaboration demonstrates our commitment to support the ‘Make in India’ government initiative and we look forward to generating future business growth in India. The NEVIC Solution Center will be a turning point as OEMs and Tier 1s will now have access to secure system solutions and can leverage Tata Elxsi’s Electrification expertise for use case-specific customizations.”

- Taizo Hayashi, Vice President of Automotive New Business Creation Division, Renesas

Where we are now

The first version of our Battery Management System (BMS) features all essential functions, extensively tested and validated. It allows rapid customization to meet specific customer needs. Microcontroller and Analog Front End (AFE) can meet the functional safety requirements, enabling safety at various levels. Portable MATLAB/Simulink models and a scalable architecture ensure versatility across vehicle segments.

Services rendered

Tata Elxsi

- Multi-chemistry support

- Scalable Architecture

- Multiple Modes for cell balancing

- Isolated AFE communication

- Diagnostics and Calibration

- System configuration through GUI

- Power saving Modes

- Battery pack Fault management

- Optimum fault Response time

- Effective thermal runaway detection