Case Study

Design and Development of Motor Control Unit (MCU) for Electric Vehicles

Reduced Time to Market

Cost Optimization in Design & Development

More Configurability and Performance

Background

In the rapidly evolving Electric Vehicle (EV) industry, the need for an efficient Motor Controller ECU (Electronic Control Unit) is paramount to ensure enhanced safety, reliability, and performance.

Tata Elxsi, in partnership with Renesas Electronics, embarked on a collaborative effort under the Next Generation EV Innovation Center (NEVIC).

We worked on developing a versatile Motor Control Unit (MCU) for electric vehicles designed to accommodate a broad spectrum of motors and position sensors. This initiative not only showcases our innovation prowess, but it also sets a new benchmark for technological excellence in the EV industry.

Challenge

Meeting the surging demand for Electric Vehicles has put significant pressure on OEMs to expedite their product development and launch.

The intricacy of incorporating advanced motor control algorithms, optimizing performance, and ensuring compatibility with diverse position sensor types, throttle, and brake modules available in the market poses a challenge.

Furthermore, there is additional complexity added by the laborious and complex procedure of motor testing with position sensor and phase-wire sequence, angle offset, and calibration for various throttle and brake modules.

Solution

Tata Elxsi and Renesas jointly developed this Motor Control Unit (MCU) on RH850C1M controller platform with all essential features for the motor control, safety and performance.

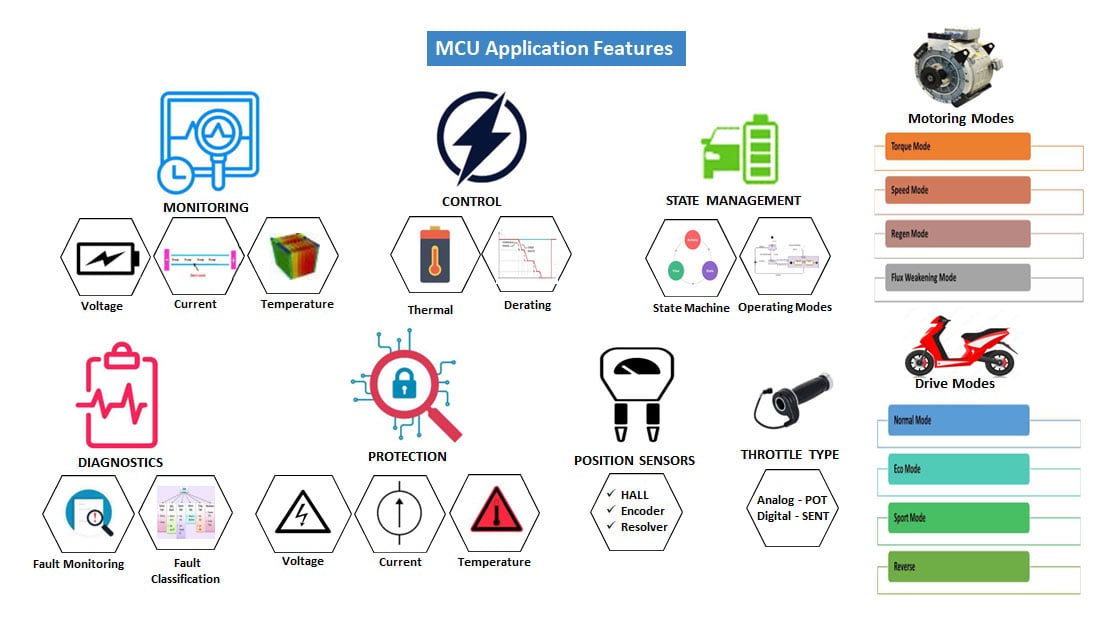

The solution featured a built-in motor control strategy along with multiple driving modes, Torque and speed control, cruise control, Flux weakening, thermal derating, and comprehensive fault detection and fault handling capabilities, ensuring compliance with safety and performance requirements.

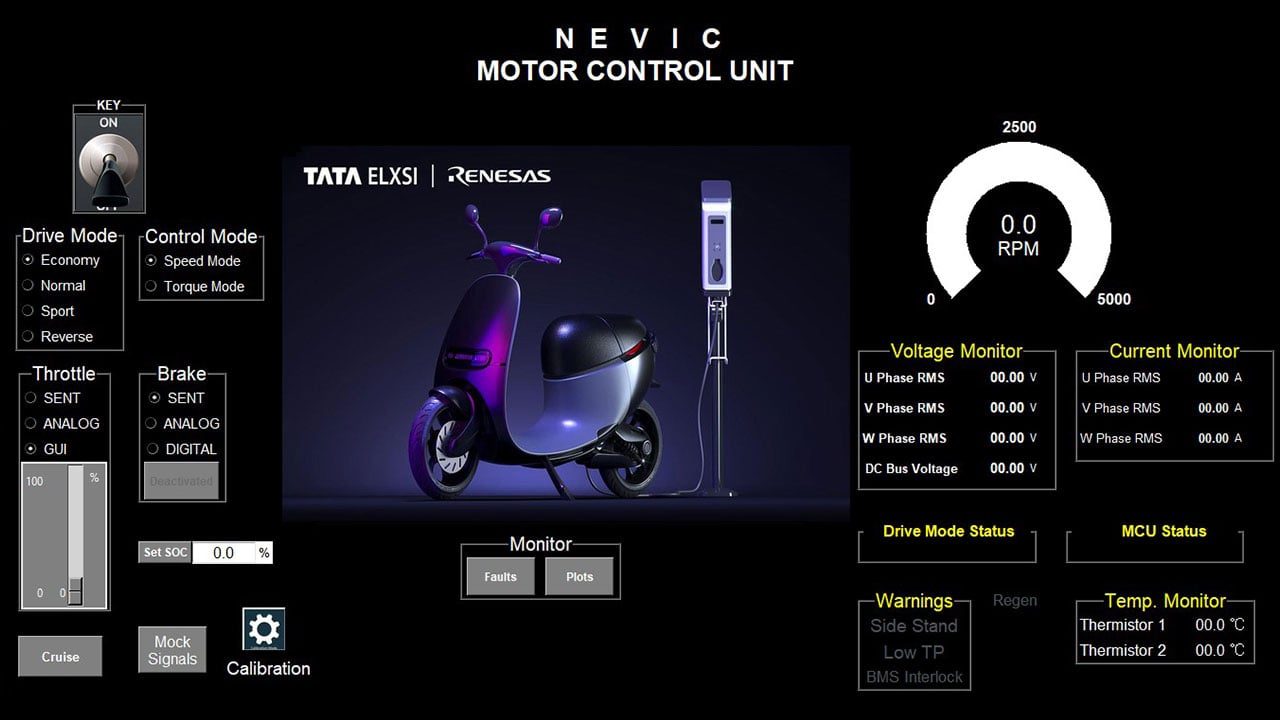

Furthermore, a high degree of flexibility is offered with adjustable pulse width modulations, automatic throttle, brake and angle offset calibration, and a Graphical User Interface (GUI) for the system configuration.

The modular and scalable design enabled seamless integration across diverse EV applications, including 2W,3W,4W and above.

Impact

This comprehensive solution serves as a one-stop shop for Motor Control Unit (MCU) in embedded hardware, software, testing, and validation requirements, ensuring seamless development and integration and hence less time to the market.

Supporting multiple motors and sensors, it offers versatility and adaptability to diverse electric vehicle applications. Furthermore, its inclusion of diagnostic and protection features enhances the overall reliability and safety of any traction application, setting new benchmarks for performance and dependability.

By ensuring efficient battery voltage usage, minimizing motor harmonics, torque ripple, and enabling the motor to operate above its rated speed, we significantly extend the vehicle's driving range, amplifying its impact and efficiency on the road.

"Renesas is pleased to work with Tata Elxsi, a proven leader in design and technology services for the automotive industry. This collaboration demonstrates our commitment to support the ‘Make in India’ government initiative and we look forward to generating future business growth in India. The NEVIC Solution Center will be a turning point as OEMs and Tier 1s will now have access to secure system solutions and can leverage Tata Elxsi’s Electrification expertise for use case-specific customizations.”

- Taizo Hayashi, Vice President of Automotive New Business Creation Division, Renesas

Where we are now

As of now, significant progress has been made on the development, testing, and validation of all essential features of the MCU, which have been successfully implemented on the first version of the Motor Control Unit hardware for electric vehicles. Notably, the microcontroller is functional safety capable, simplifying the achievement of required ASIL levels for different electric vehicle application requirements.

Additionally, the system boasts effortless configuration for any motor types and position sensors, while its scalable architecture ensures adaptability across diverse vehicle segments.

Services rendered

Tata Elxsi

- Scalable Architecture

- Multiple motor control methods

- Configurable motor types and sensor types

- System configuration through GUI

- Multiple Operating Modes

- Derating and performance optimization

- Fault detection and Fault handling

- Diagnostics and Calibration