Case Study

Smart Monitoring for Cloud Kitchens

Faster Proactive Maintenance

Increase in Productivity

Reduction in Maintenance Cost

Background

Cloud kitchens are transforming the food industry by providing efficient, large-scale meal preparation using smart appliances. Our client, a leading Japanese appliance manufacturer, monitored multiple appliances, such as rice cookers, toasters, and other home appliances, which was critical in maintaining high operational standards.

Traditional fault detection relied on visible performance issues or customer feedback, often resulting in delays. A proactive, AI-driven approach was needed to detect early signs of inefficiency, streamline operations, to ensure consistent quality and timely food preparation.

Challenge

The main challenge was to detect early signs of inefficiency or malfunction in rice cookers before they impacted kitchen operations. Manual inspections of smart appliances are time-consuming, and breakdowns would result in lost time and reduced kitchen productivity. With cloud kitchens operating on tight timelines, delays in identifying faults compromised productivity and service quality.

Some of the key challenges included:

- Inconsistent cooker performance monitoring

- Difficulty identifying early malfunctions

- Productivity losses from undetected issues

Solution

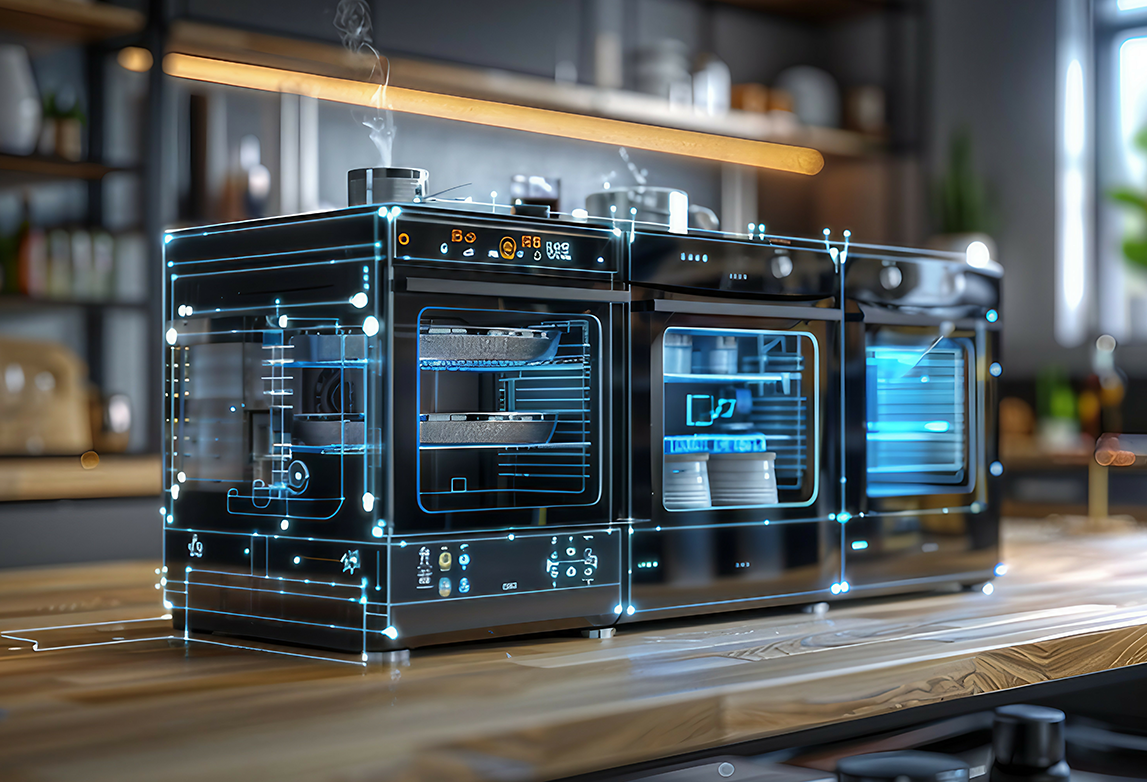

An AI-enabled smart appliance monitoring solution was developed using smart plugs installed in rice cookers to collect data on cooking cycles and power usage. This data was transmitted to a server, where Machine Learning (ML) algorithms analyse patterns over time.

The process starts with data collection via smart plugs, tracking daily cooking cycles. When anomalies were detected, the system flagged issues and generated alerts to prompt timely maintenance. Visual dashboards provided clear insights into each appliance’s health, helping teams act before problems escalated, reducing downtime and improving reliability.

Impact

The AI-driven system delivered significant operational improvements by offering real-time insights into appliance health. Early detection of faulty rice cookers helped prevent major breakdowns, enhancing both efficiency and service reliability,

- 30% Faster Maintenance: Faster identification of faults allowed preemptive repairs, minimising disruptions.

- 18% Increase in Productivity: Reduced appliance downtime led to more efficient kitchen operations.

- 25% Cost Savings: Predictive Maintenance cut emergency repair costs, yielding substantial savings.

This solution not only enhanced operational efficiency, but also set the foundation for scaling AI monitoring across other smart appliances in cloud kitchens.

Services rendered

Tata Elxsi

- Assessment & Initial Consultation

- Smart Plug Installation

- Data Collection & Transmission

- Machine Learning Algorithm Development

- Visualisation & Analytics Dashboard

- Fault Detection & Alert System

- Testing & Optimisation

- Ongoing Support & Maintenance